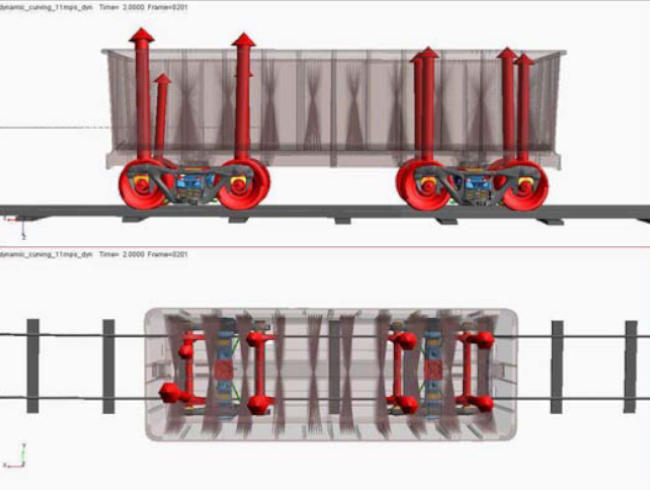

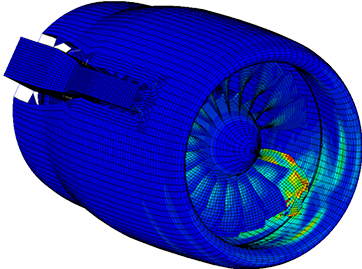

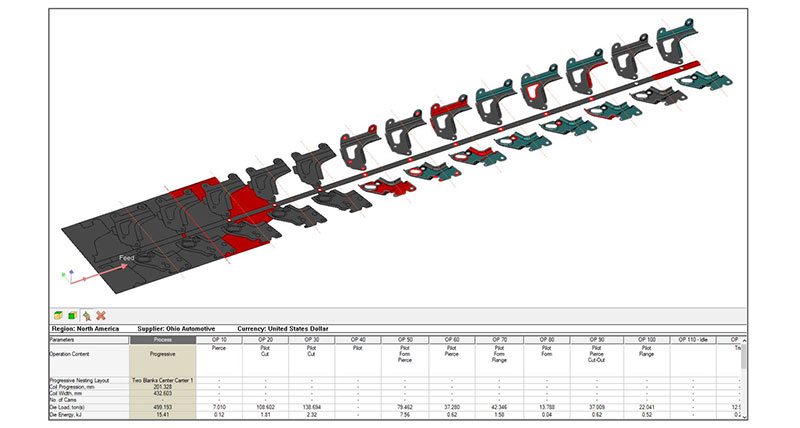

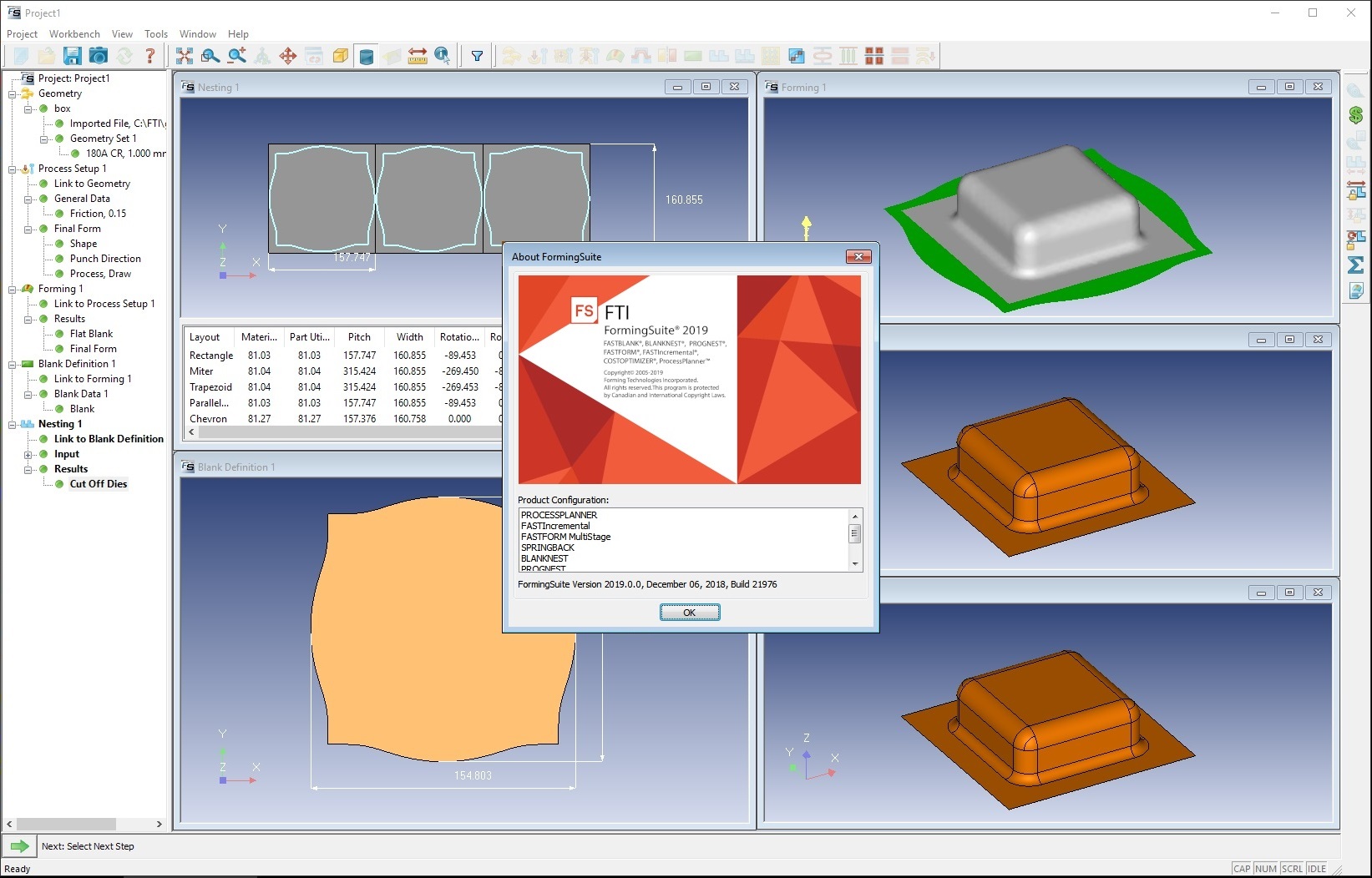

Running through a battery of simulations, VI-Rail allows to determine the vehicle stability, derailment safety clearance, track load, passenger comfort, and more. The performance of a railway vehicle design can be optimized virtually in the computer, before cutting a single piece of metal or running a single physical test.

Simulation gives users immediate answers to their engineering questions. They quickly see and understand how any kind of design change will affect vehicle performance. VI-Rail is built upon the MSC Software product MSC Adams, widely recognized as the world’s leading mechanical system simulation tool.

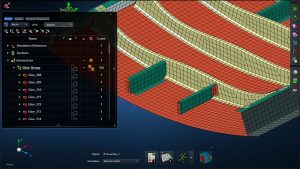

VI-Rail users can instantly see the effects of design changes on railcar performance in high-speed animation. They can easily detect component interferences, excessive wear, instability, and performance limitations. Users can also plot key parameters in graphs to compare results from different designs.

- Quickly build, test, and refine railcar designs, exploring many “what-if” alternatives. A user can, for example, change springs with only a few mouse clicks, instead of having to wait for a mechanic to install new springs, as required with physical testing

- Easily vary the kinds of analyses being performed. With simulation, there’s no need to modify physical instrumentation, test fixtures, and test procedures

- Work in a secure testing environment, without fear of losing critical data to instrument failure

0-2862-1188

0-2862-1188