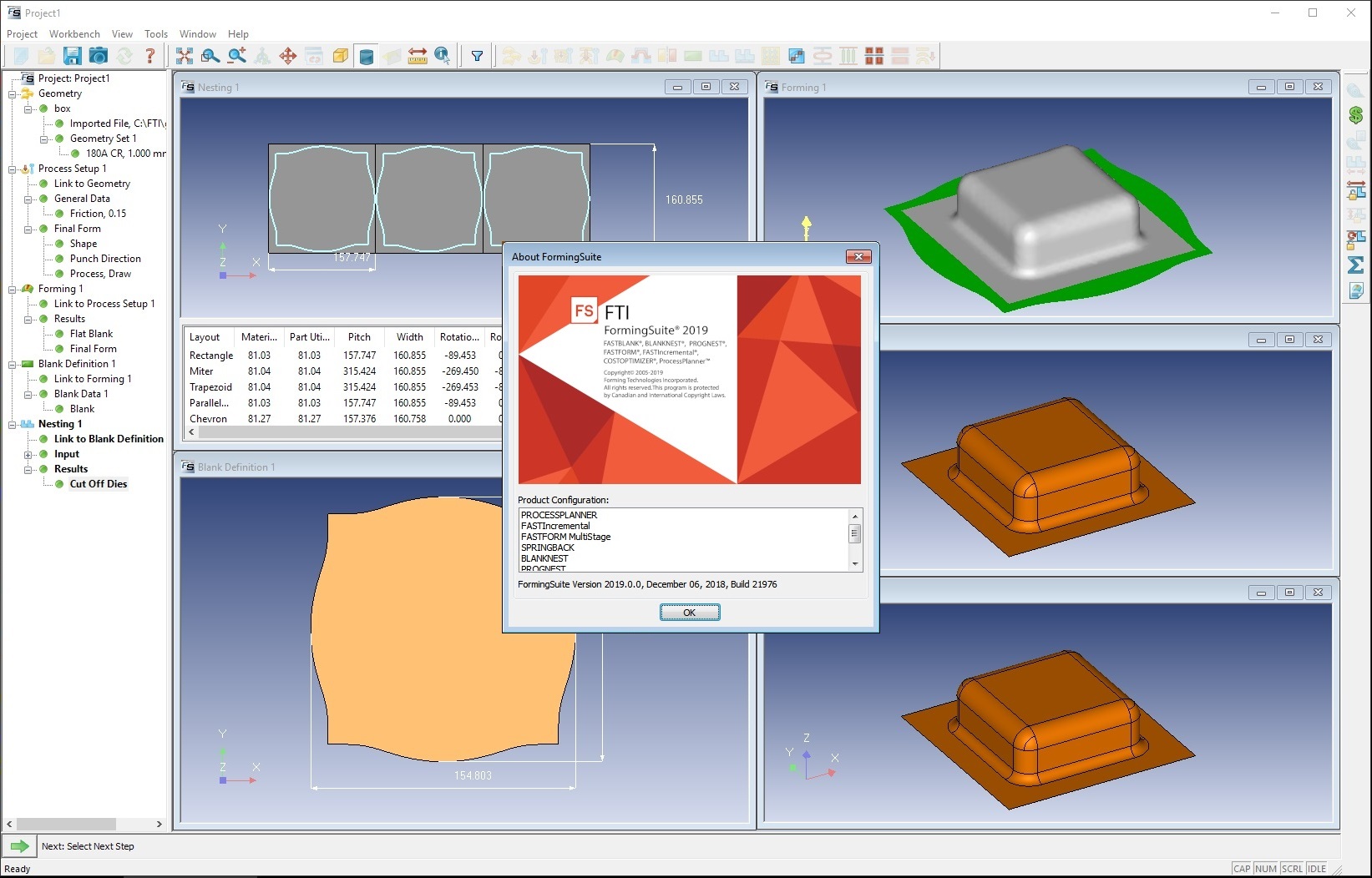

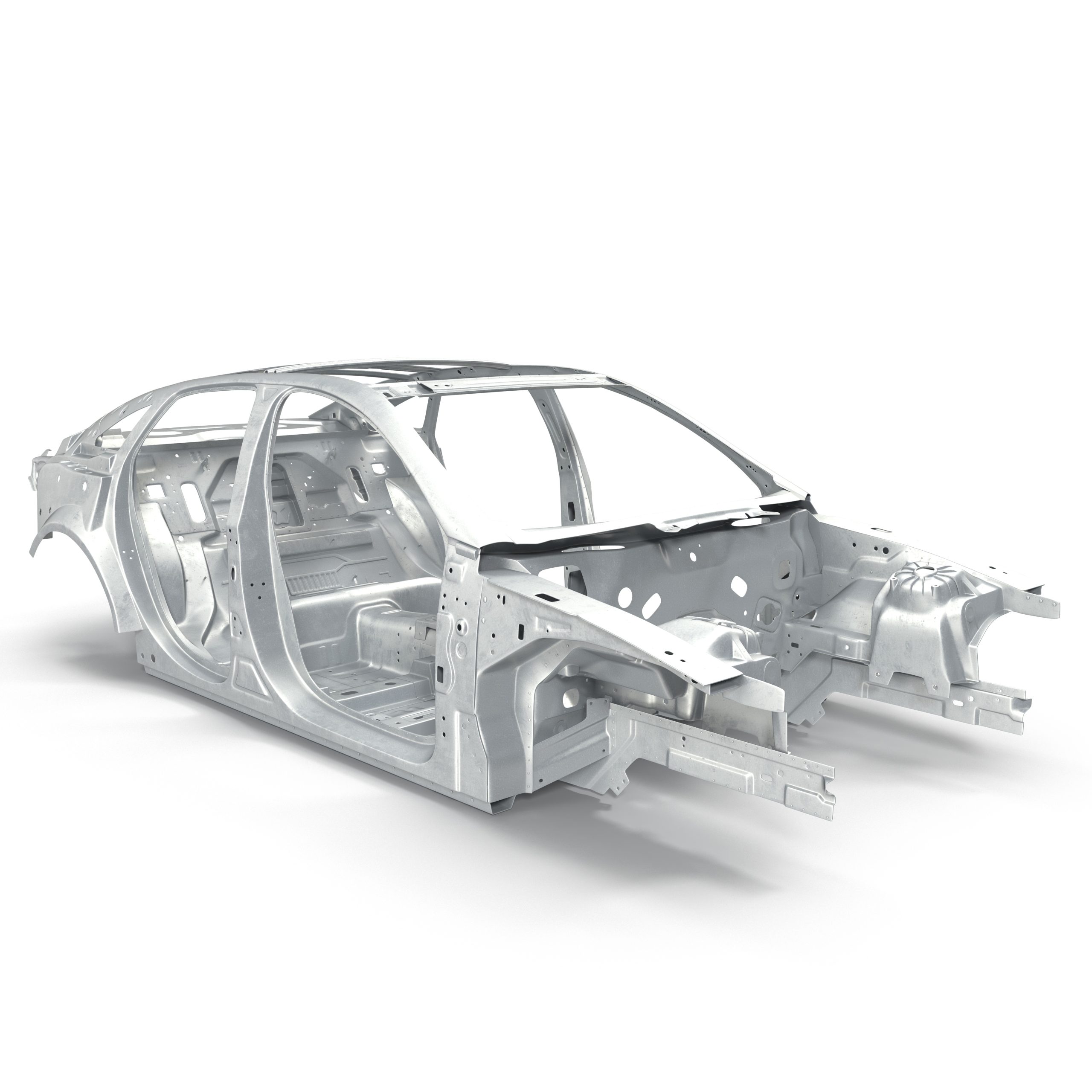

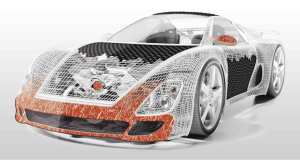

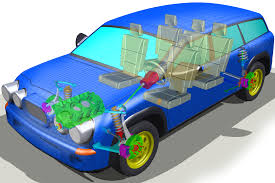

COSTOPTIMIZER is a software solution that enables Cost Engineers to develop quotations and estimates for piece part costing by creating precise blank shape developments, performing initial formability risk assessment and establishing target costs for sheet metal components. Substantial material costs and weight reductions can be realized from optimizing nesting layouts and identifying critical nest points for minor changes to product design. COSTOPTIMIZER provides the required information to evaluate multiple manufacturing scenarios for optimal material usage that generates cost and weight savings.

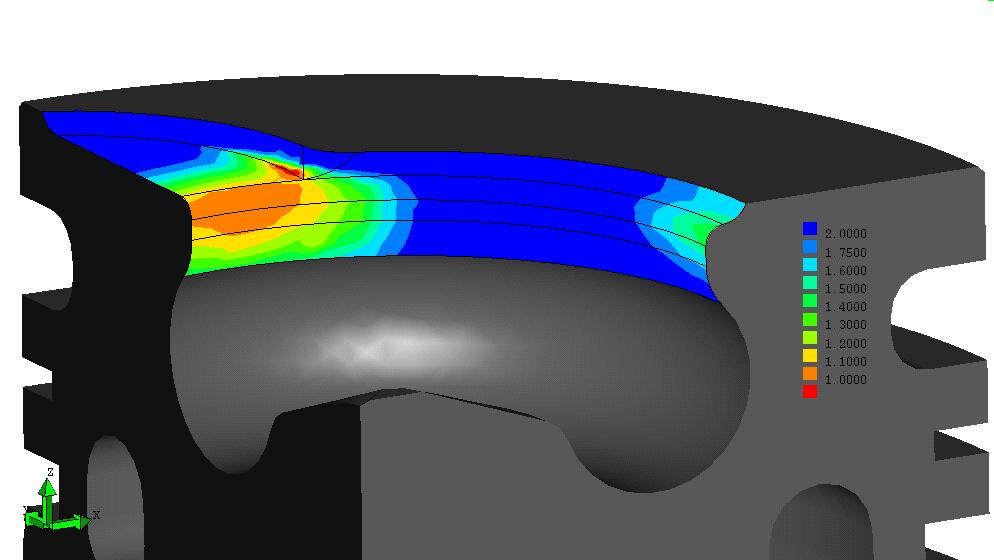

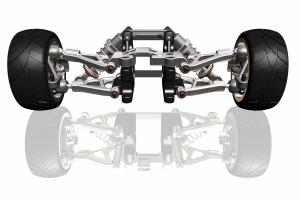

Cost Engineering is critical activity devoted to the management of project costs, involving such activities as estimating, cost control, cost forecasting, investment appraisal and risk analysis. The cost of a part is determined from geometric shape, material type, manufacturing process (progressive, transfer, tandem) and investment. By implementing a standard methodology for creating, tracking, analyzing and communicating the contents of a quote, an organization can impose a disciplined approach to the quotation process. The key objective of cost engineering is to arrive at accurate cost estimates and schedules and to avoid cost overruns and schedule slips.

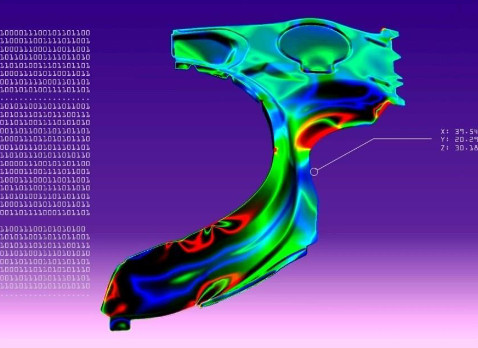

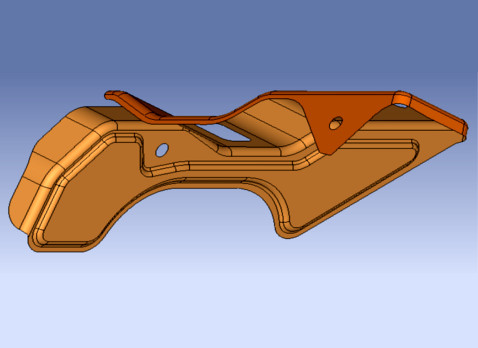

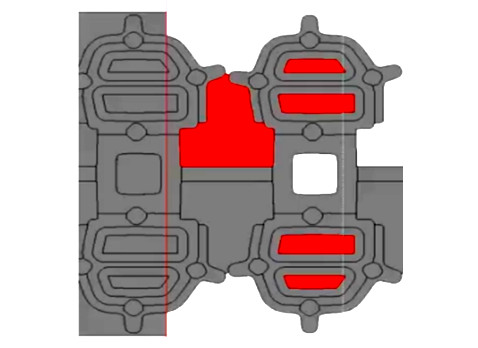

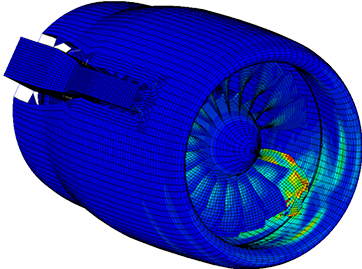

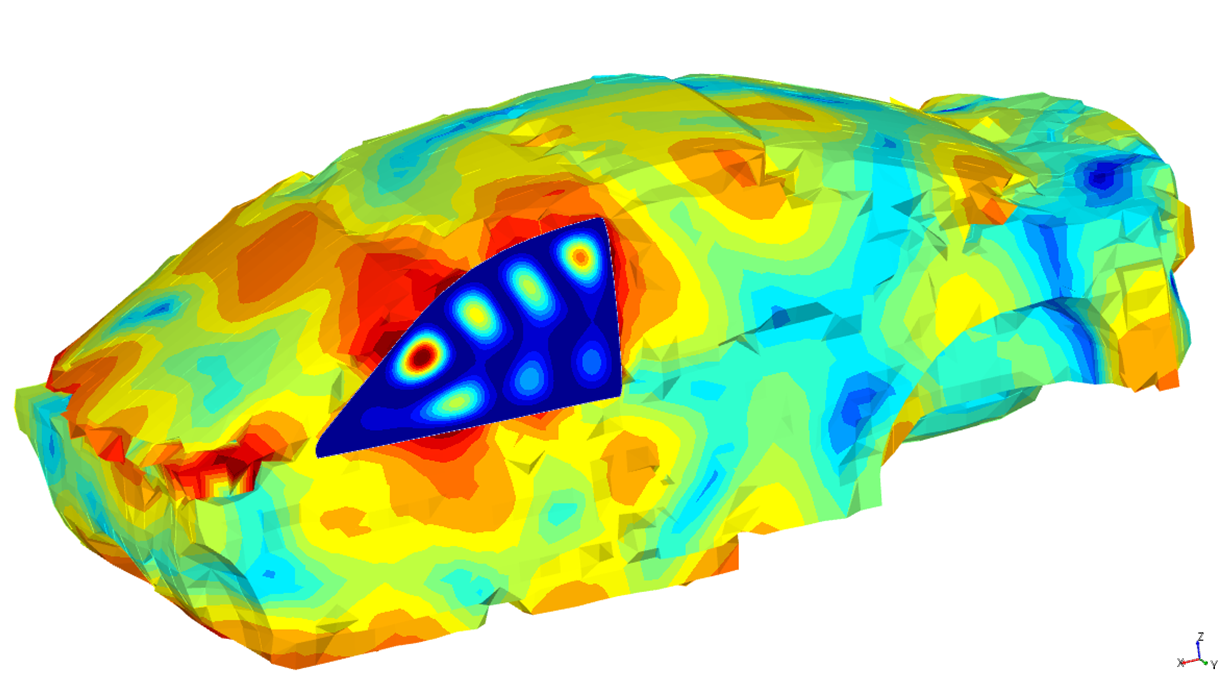

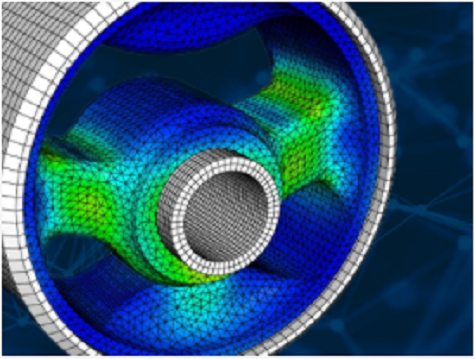

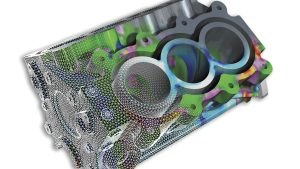

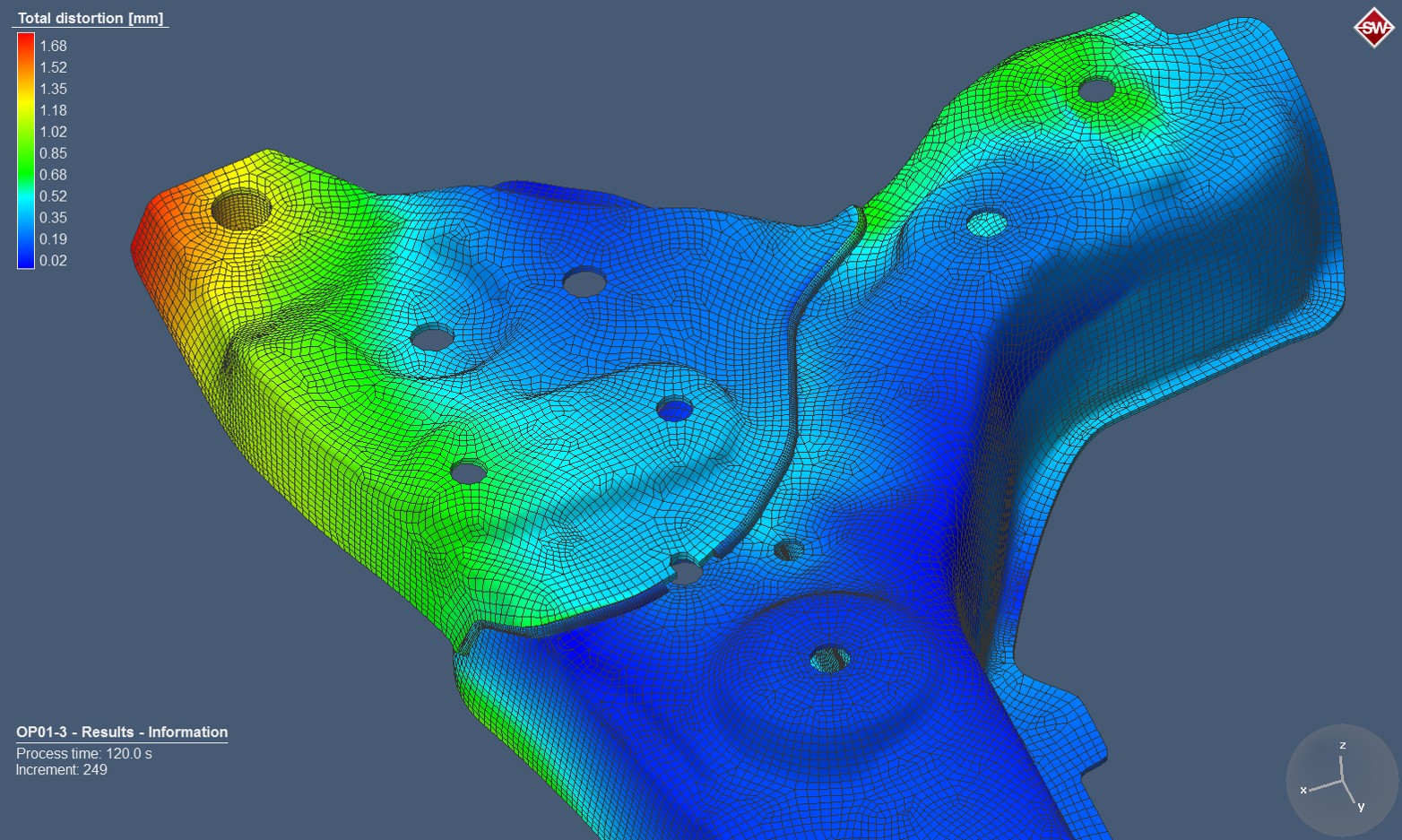

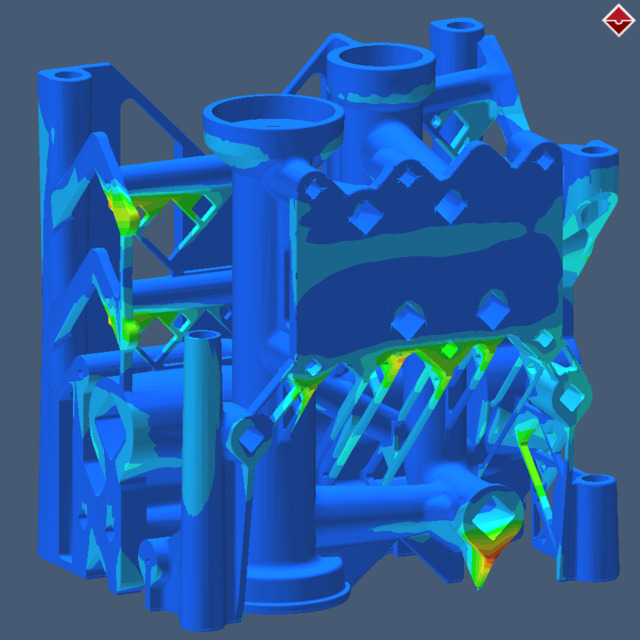

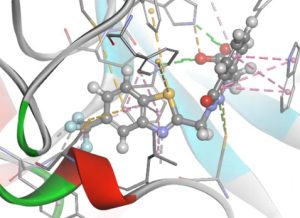

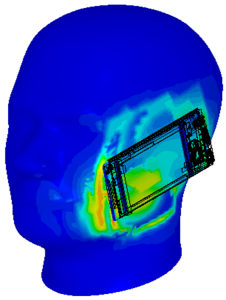

COSTOPTIMIZER uses a scientific physics-based approach to develop accurate blank shapes (CHI Solver) based on forming process, material properties and accounts for stretch and deformation of 3D product geometry. Cost engineers benefit from developing self-confidence (internal know-how), quick and accurate material projection, improving quote accuracy, suggesting product changes that impact material utilization, evaluating part manufacturing concerns, and promoting confidence and trust with your customers.

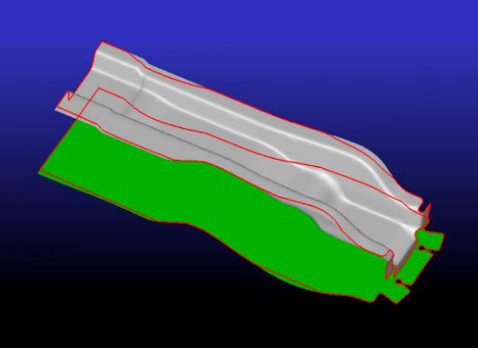

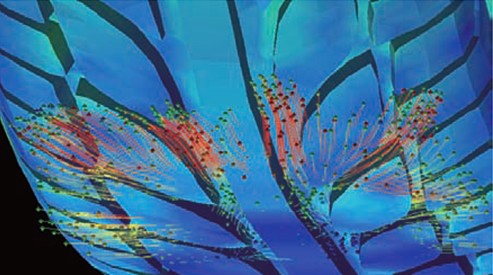

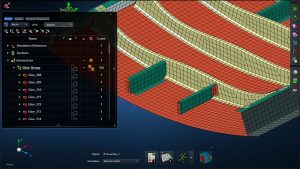

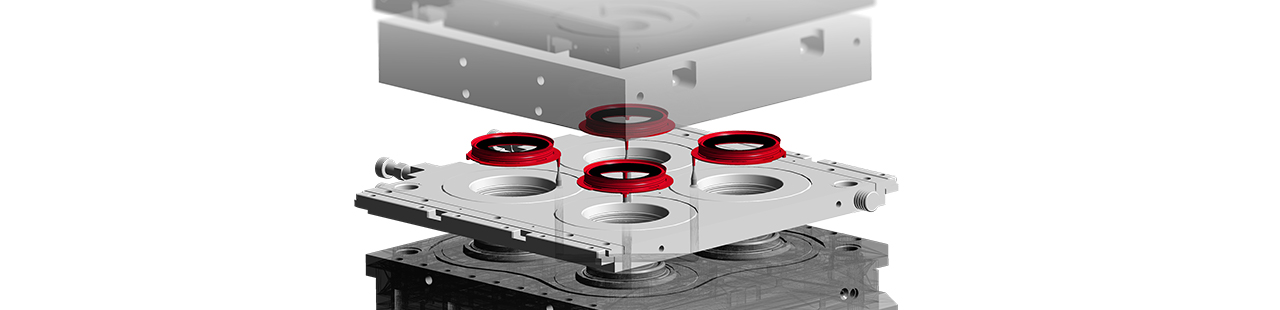

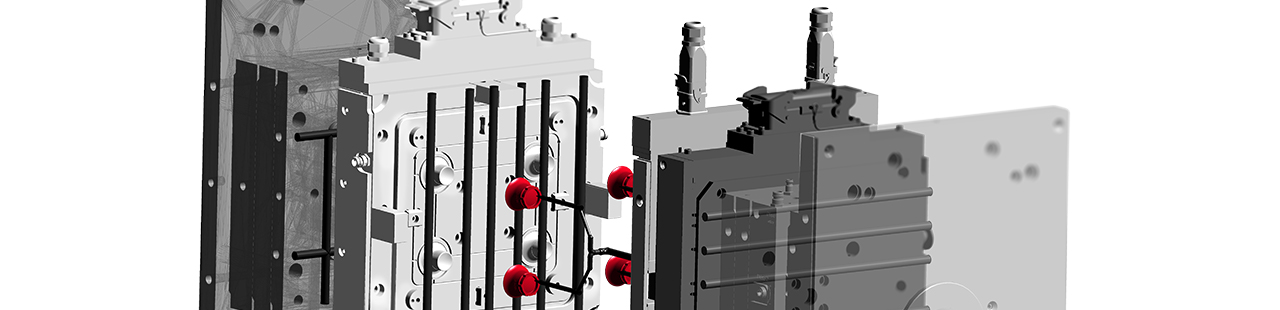

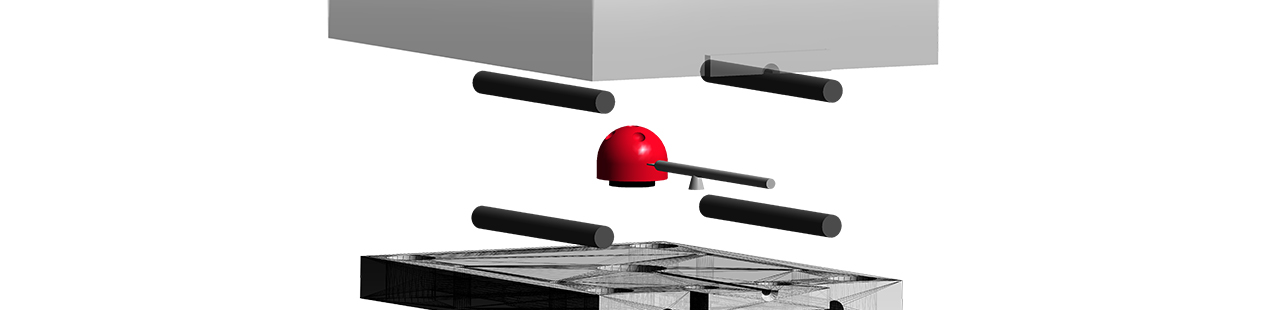

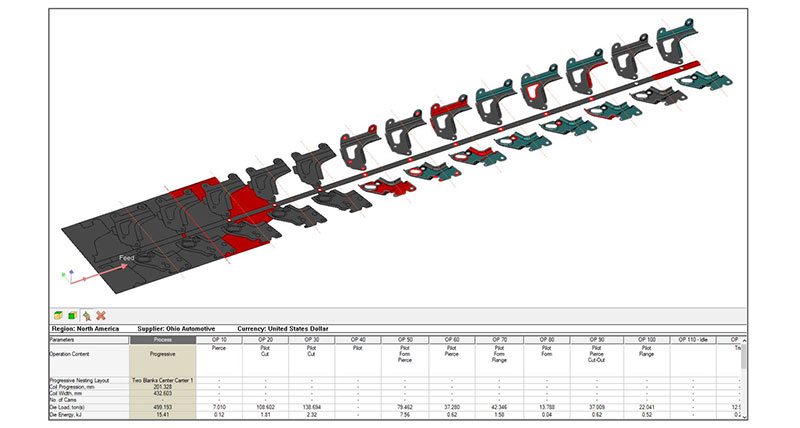

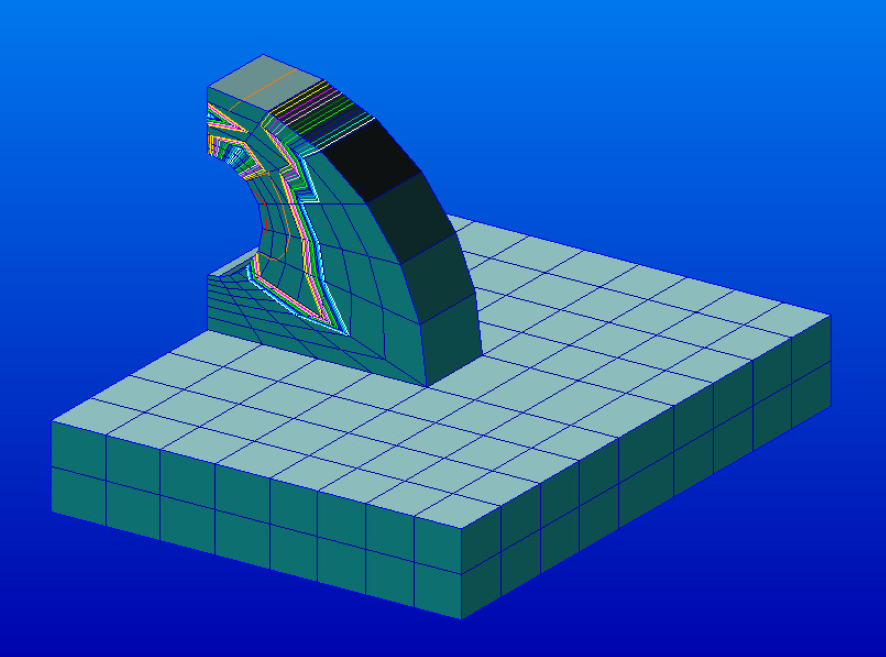

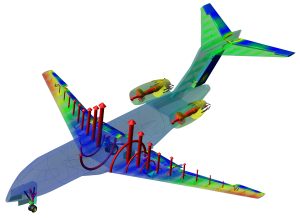

Several nesting layouts can be developed and evaluated to maximize material utilization based on coil width and pitch constraints. Nests are generated for 1-up, 2-up, 2 blanks and mirrored arrangements from coils for high volume production in line dies and progressive dies or low volume production from slit sheets.

Highlights

- Cost engineers gain self-assurance in quoting and estimating sheet metal components

- Scientific, physics-based approach quickly predicts accurate material projection

- Improves quote accuracy to better position your company

- Suggests product design changes that impact material utilization

- Evaluates part manufacturability concerns

- Promotes confidence and trust with your customers/suppliers

Other packages:

COSTOPTIMIZER ADVANCED ซอฟต์แวร์ที่รวบรวมความสามารถในการวิเคราะห์ความเป็นไปได้ของโครงการขึ้นรูปโลหะแผ่น การพัฒนา Blank และการทำ Nesting ที่เหนือกว่า โดยการลดจำนวนการเปลี่ยนแปลงทางด้านวิศวกรรมที่อาจเกิดขึ้นเพื่อใช้วัตถุดิบอย่างมีประสิทธิภาพมากที่สุด

CostOptimizer Professional for Progressive and Line Dies ซอฟต์แวร์ที่รวบรวมความสามารถในการวิเคราะห์ความเป็นไปได้ของโครงสร้างการขึ้นรูปโลหะแผ่นในไลน์การผลิตแม่พิมพ์ (Line Dies) ไปจนถึงวิเคราะห์ความเป็นไปได้ของโครงสร้างการขึ้นรูปโลหะแผ่นแบบต่อเนื่อง (Progressive) เพื่อการพัฒนา Blank และการทำ Nesting ที่เหนือกว่า

0-2862-1188

0-2862-1188