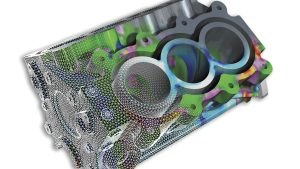

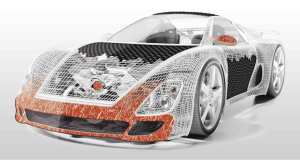

Simulation is establishing itself as one of the most innovative technologies in Powder Injection Molding, as it has proved to drastically reduce the development time for new parts and the costs associated with iterations in the production of new molds. With unique features developed specifically for the PIM industry and its highly developed thermal solver, SIGMASOFT® is the market leader for PIM simulation and nowadays the only software available to describe the particular rheological behavior of powder filled materials and the complex thermal interactions between mold components and feedstock.

Highlights

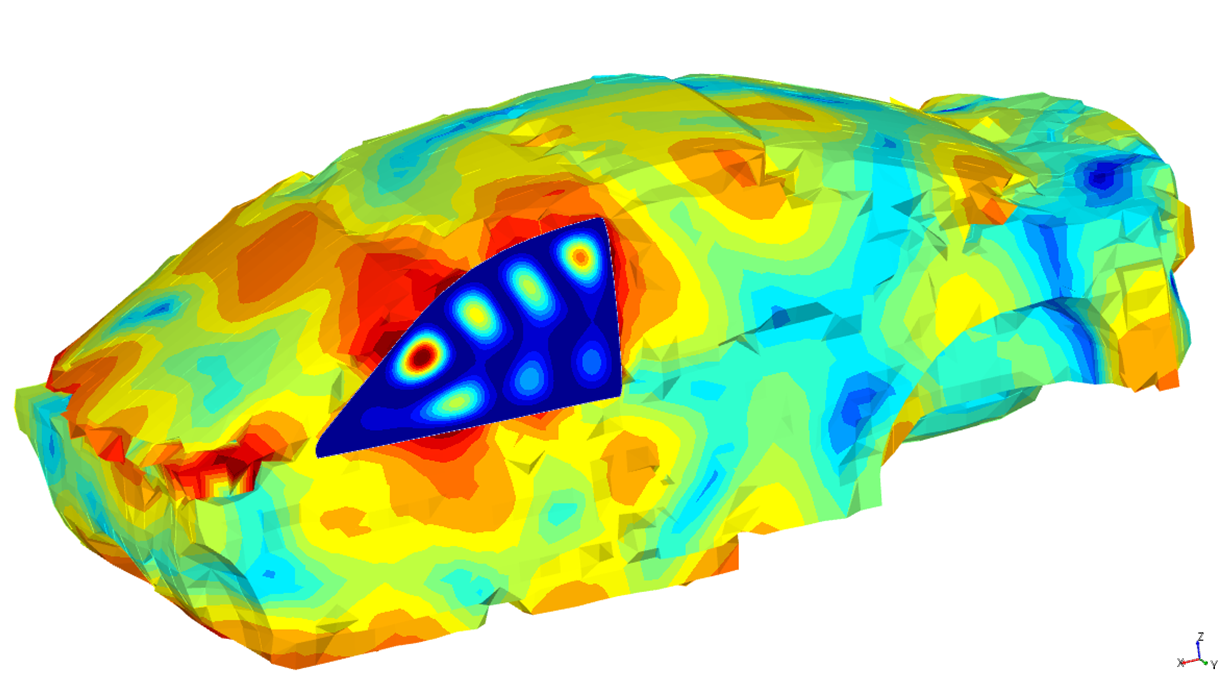

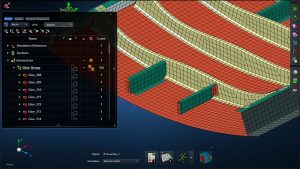

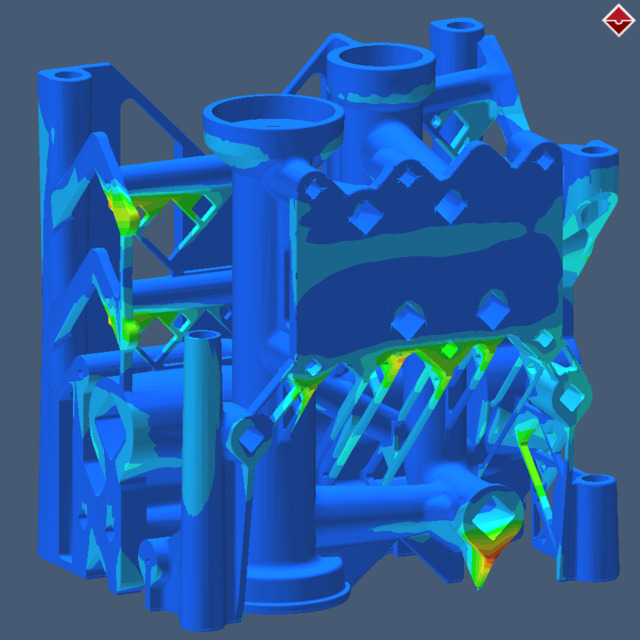

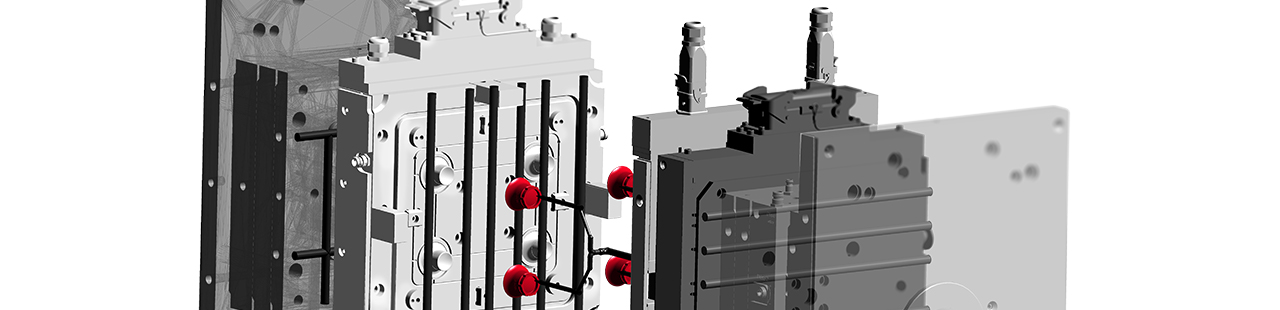

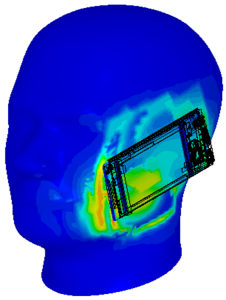

- Comparison of different thermal concepts over part quality and productivity

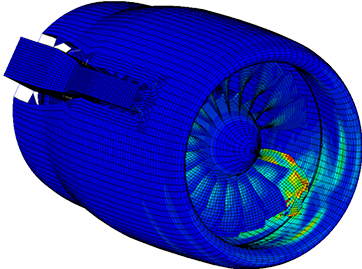

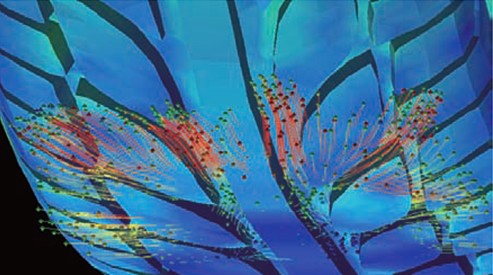

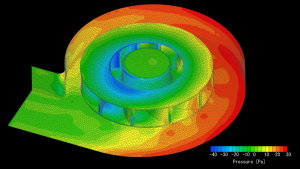

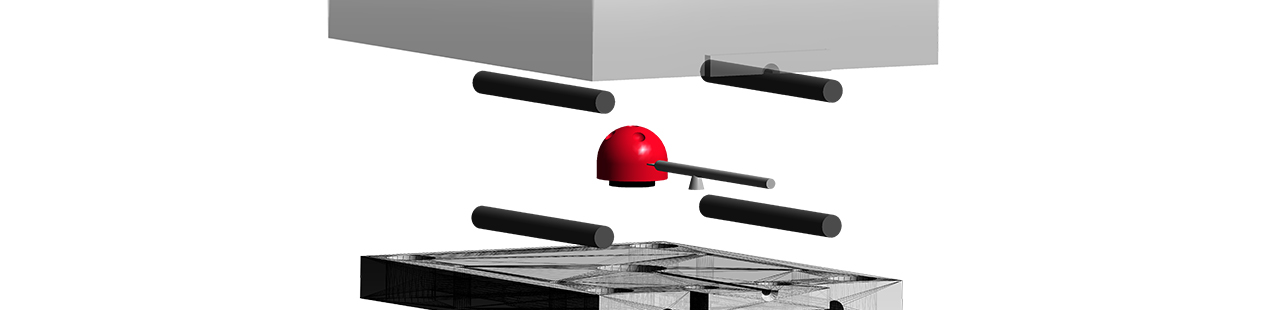

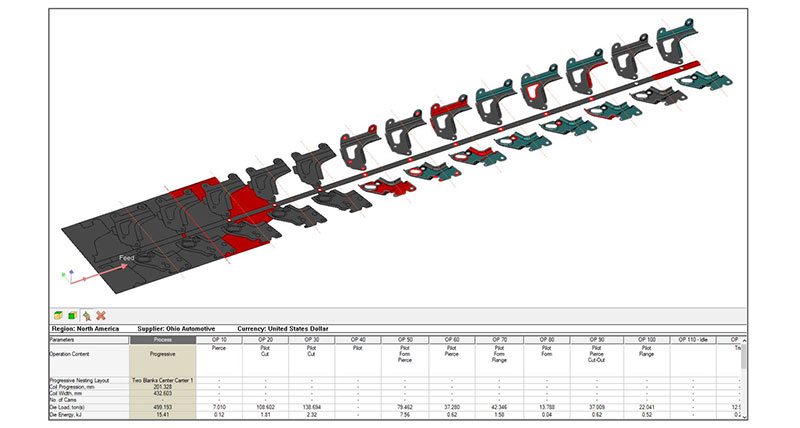

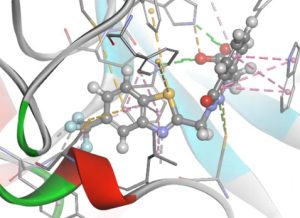

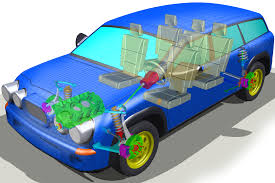

- Prediction of the filling behavior

- Prediction of flow front propagation, fountain flow, plug flow behavior and jetting effects

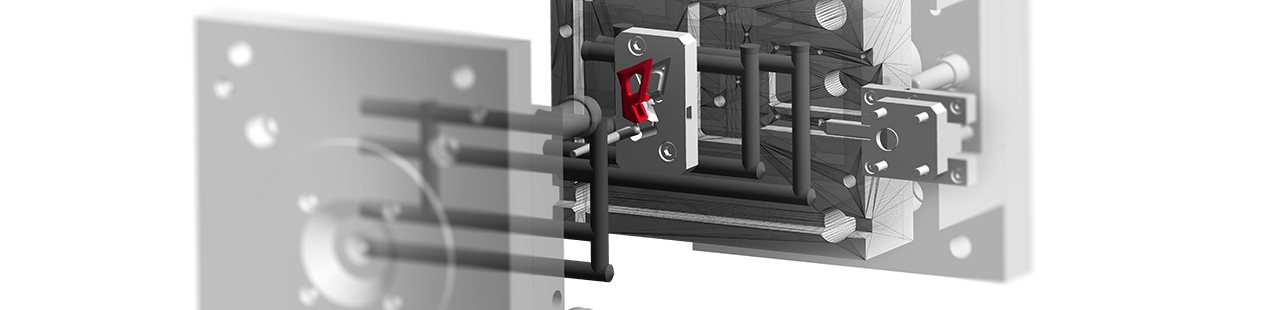

- Identification of possible particle segregation during filling

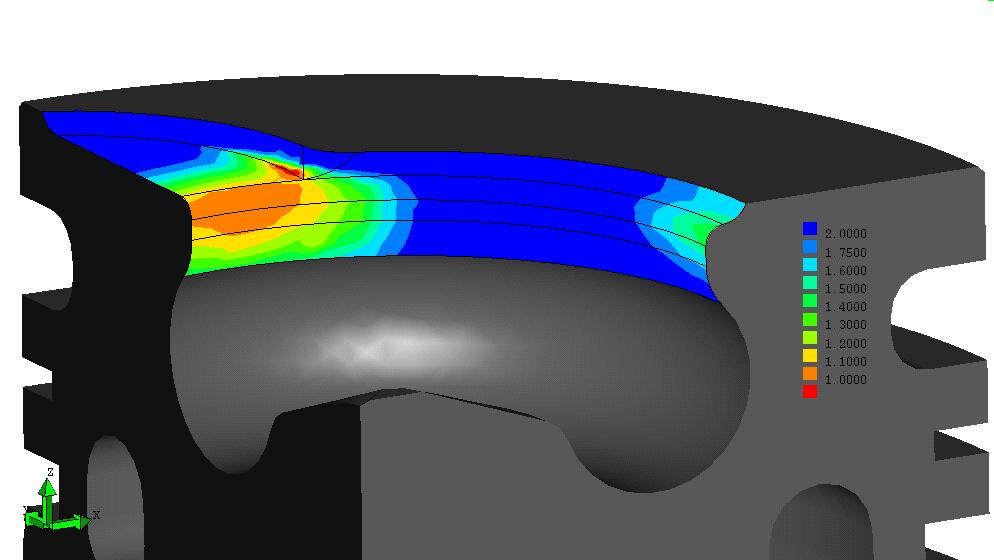

- Simulation of the increase of viscosity at low shear rates

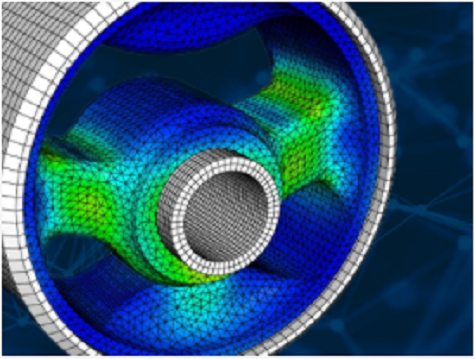

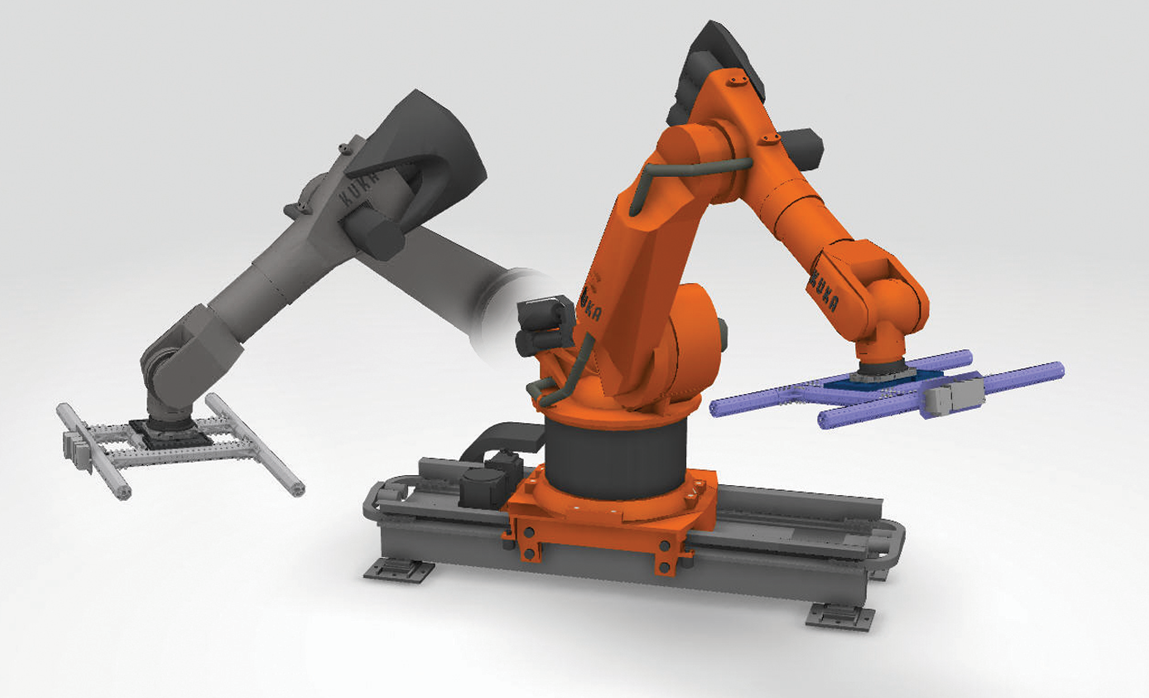

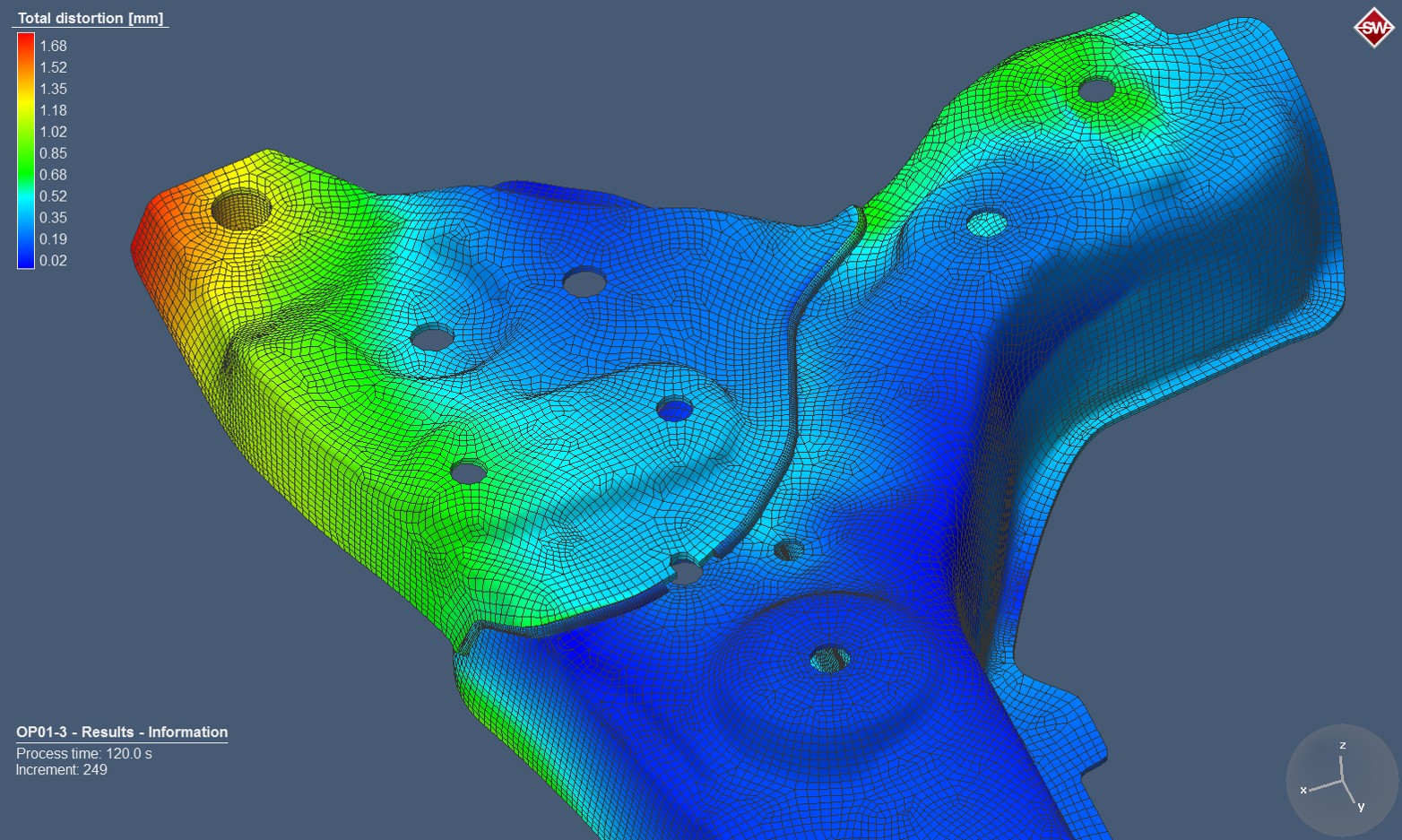

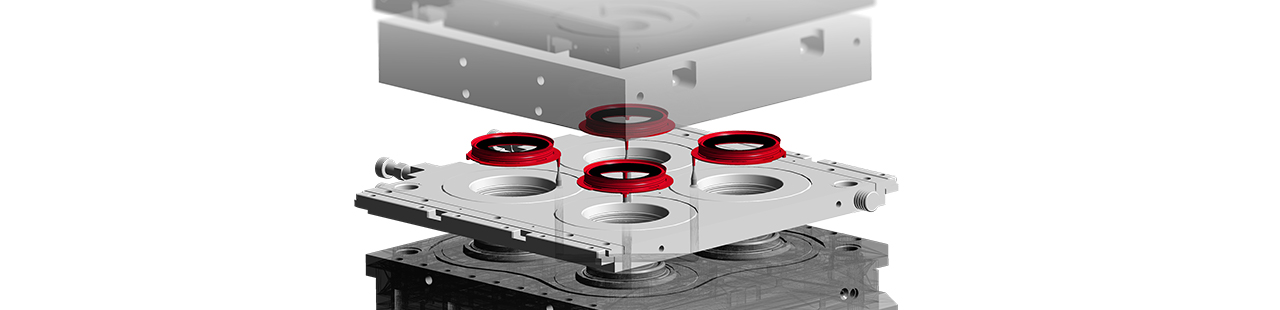

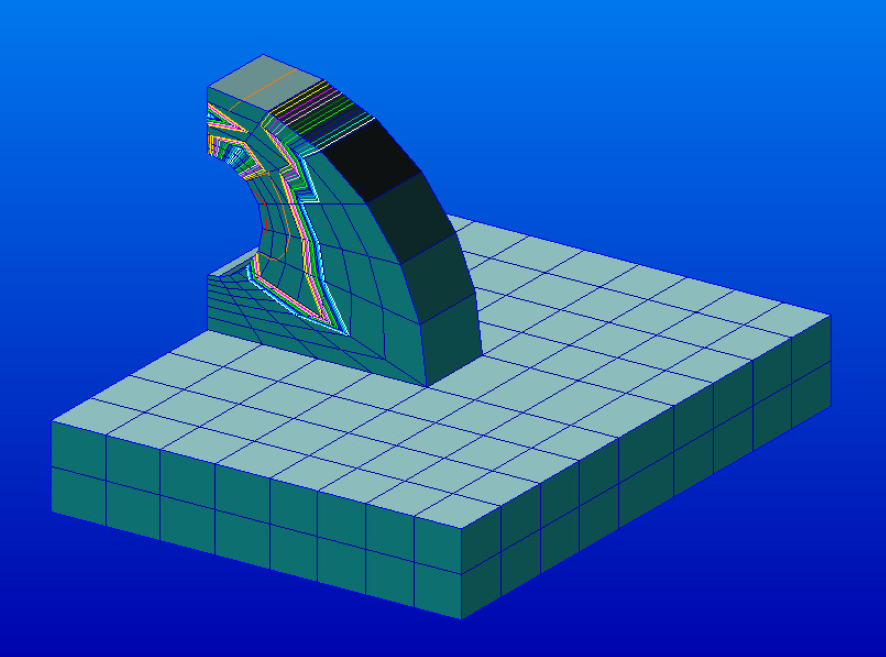

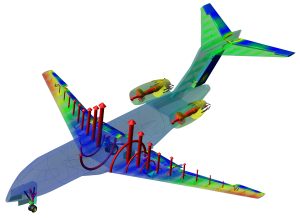

- Core and insert deformation during filling

- Clamping force calculation

- Holding (packing) simulation

- FEM Interface to MARC, Ansys, Abaqus, etc.

0-2862-1188

0-2862-1188